In a significant advancement for the food processing industry, Nothum Food Processing Systems has introduced an innovative frying solution that promises to transform operations. The EzFlow Fryer Oil Filter is designed to address common challenges in frying processes with its compact and efficient design. This new system reduces internal chamber pressure dramatically while extending oil life, improving product quality, and cutting production costs. Enhanced safety features and user-friendly operation further distinguish this invention, making it a valuable asset for various sectors within the food industry.

A Closer Look at the EzFlow Fryer Oil Filter's Breakthrough Technology

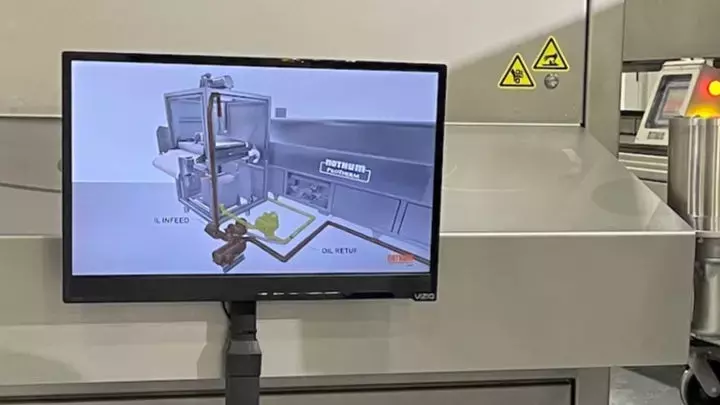

In the heart of the culinary world, Nothum Food Processing Systems has made waves by launching the EzFlow Fryer Oil Filter. This device, born from meticulous research and development, tackles the complexities of frying foods with unprecedented efficiency. Utilizing a patented sealing mechanism paired with advanced filtration techniques, EzFlow minimizes pressure within its chambers by up to 75% compared to rival systems. It operates continuously at 50 gallons per minute, ensuring smooth and uninterrupted performance.

To ensure optimal safety and operational excellence, EzFlow incorporates sophisticated monitoring systems. These systems meticulously track critical parameters such as internal chamber pressure, oil temperature, sediment cake drying, and gasket condition. Alerts are displayed promptly for routine maintenance checks, guaranteeing seamless operation. The setup process is streamlined for ease of use, fitting effortlessly into existing fryer setups, including Nothum’s own ProTherm Continuous Thermal Fryer for battered and breaded items.

The filtering cycle is initiated with a single button press, initiating an automated sequence that filters sediments and dries the resulting cake before entering bypass mode. Upon completion, the system prepares itself with fresh paper for the next cycle. This continuous process not only enhances productivity but also contributes to cost savings and waste reduction.

Nothum, under the umbrella of Fortifi Food Processing Solutions, specializes in creating a variety of solutions aimed at minimizing downtime and boosting productivity across industries like poultry, seafood, appetizers, alternative proteins, and snack foods. By supporting these sectors in maximizing flavor and reducing waste, Nothum continues to lead the charge in innovation and efficiency.

From a journalist's perspective, the introduction of EzFlow marks a pivotal moment in the evolution of food processing technology. It exemplifies how forward-thinking companies can leverage cutting-edge engineering to solve real-world problems. For readers, this innovation underscores the importance of investing in sustainable and efficient technologies that not only enhance business operations but also contribute positively to environmental sustainability. EzFlow represents a step toward smarter, greener practices in the food industry, setting a benchmark for future innovations.