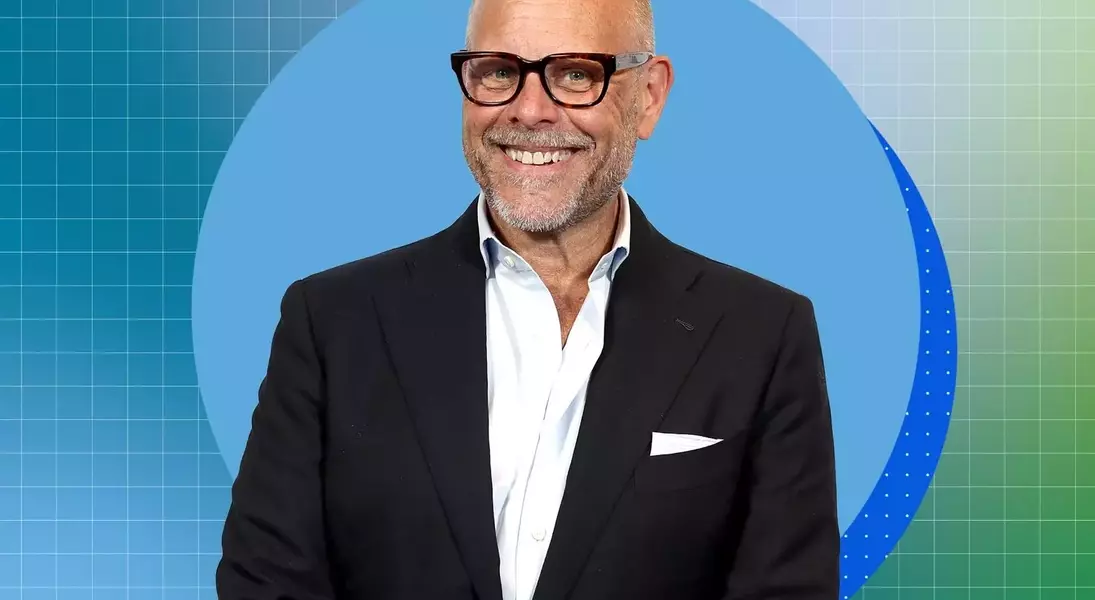

When preparing for major holiday meals, neglecting to defrost a large frozen turkey can lead to significant culinary distress. Traditional thawing methods often demand several days of careful planning, making quick-thaw solutions highly appealing. Celebrity chef Alton Brown introduced a novel technique involving an aquarium pump to accelerate this process for chickens, prompting an investigation into its applicability and effectiveness for much larger birds like turkeys. This approach promises a faster alternative to conventional refrigeration, yet it introduces its own set of logistical challenges and safety considerations that warrant thorough examination.

While the aquarium pump method offers a potentially quicker route to defrosting, its practical implementation for a substantial turkey requires considerable effort and constant vigilance. Maintaining optimal water temperatures to prevent bacterial growth and managing the setup, including a large container and frequent ice additions, can be cumbersome. Ultimately, while this hack provides a viable emergency solution, it underscores the enduring advantages of meticulously planned, traditional thawing for both safety and convenience, especially when dealing with the centerpiece of a festive spread.

Exploring the Aquarium Pump Thawing Strategy

The viral thawing method championed by Alton Brown involves circulating water around frozen poultry using an aquarium pump, drastically cutting down defrosting time compared to refrigeration. This technique leverages the principle of convection, where moving water molecules transfer heat more effectively than still air, ensuring more uniform thawing. Originally conceived for smaller items like whole chickens, this approach intrigued many, including the author, to assess its viability for a large, holiday-sized turkey. The core idea is to submerge the frozen bird in a cooler filled with water, activating an inexpensive aquarium pump to create constant water movement, which in turn accelerates the heat exchange and speeds up the thawing process. This method aims to overcome the time constraints associated with conventional thawing, which can span multiple days for a large turkey, making it an attractive option for those who find themselves in a last-minute culinary predicament.

However, applying this ingenious hack to a sizable frozen turkey introduces several complexities. While a smaller chicken might thaw in a couple of hours, a 17-pound turkey demands a much longer duration, even with enhanced water circulation. The primary challenge lies in maintaining a consistent water temperature below 40°F (4°C) to prevent the proliferation of foodborne bacteria, a critical food safety concern highlighted by the Department of Agriculture. This requires continuous monitoring with a digital thermometer and frequent additions of ice, which can increase the volume of liquid in the container, necessitating periodic drainage. Furthermore, the setup itself requires a large cooler or container, an aquarium pump, and a commitment to disinfecting all equipment afterward to prevent cross-contamination. Despite its efficiency in principle, the hands-on involvement and logistical demands make it a less straightforward solution than initially perceived, suggesting that while it works, it may not always be the most practical or stress-free option for busy cooks.

Practical Challenges and Safety Measures in Accelerated Thawing

Implementing Alton Brown's rapid thawing technique for a large turkey, though scientifically sound in principle, presented considerable practical obstacles. The inherent size of a whole turkey required a spacious cooler, and the tendency of the bird to float necessitated weighting it down. Crucially, maintaining the water temperature below the critical 40°F (4°C) mark proved to be a continuous effort, requiring frequent ice replenishment, even in cold ambient conditions. This constant vigilance, coupled with the need to manage the increased water volume by draining excess liquid, transformed the supposedly 'hack' into a demanding, time-consuming task, highlighting the trade-offs between speed and convenience, and emphasizing the paramount importance of strict adherence to food safety guidelines.

Food safety experts stress the necessity of keeping thawing meat out of the bacterial 'danger zone' (40-140°F), where pathogens like Salmonella can multiply rapidly. Therefore, any accelerated thawing method must rigorously control temperature. In this experiment, despite the use of an aquarium pump to ensure uniform heat transfer through convection, the continuous manual intervention for temperature regulation and water management detracted from the method's overall appeal. While the turkey did thaw significantly faster than in a refrigerator, the 'babysitting' required, from monitoring with a digital thermometer to sanitizing equipment, made it less ideal for casual use. For those with adequate equipment and a willingness to commit the time and effort, this method can safely expedite turkey thawing, but traditional refrigerator thawing remains the most reliable and less labor-intensive option for optimal planning and peace of mind.