In the realm of advanced materials, a groundbreaking invention is set to redefine industries ranging from defense to space exploration. This innovation, known as Composite Metal Foam (CMF), was developed over a decade ago by an engineer at North Carolina State University. The material's unique properties—lightweight yet incredibly strong—make it ideal for various applications, including protection against extreme conditions such as ballistic impacts and radiation. After extensive testing, CMF is now ready for mass production, promising significant advancements in multiple sectors.

A Breakthrough Material: Stronger and Lighter Than Traditional Metals

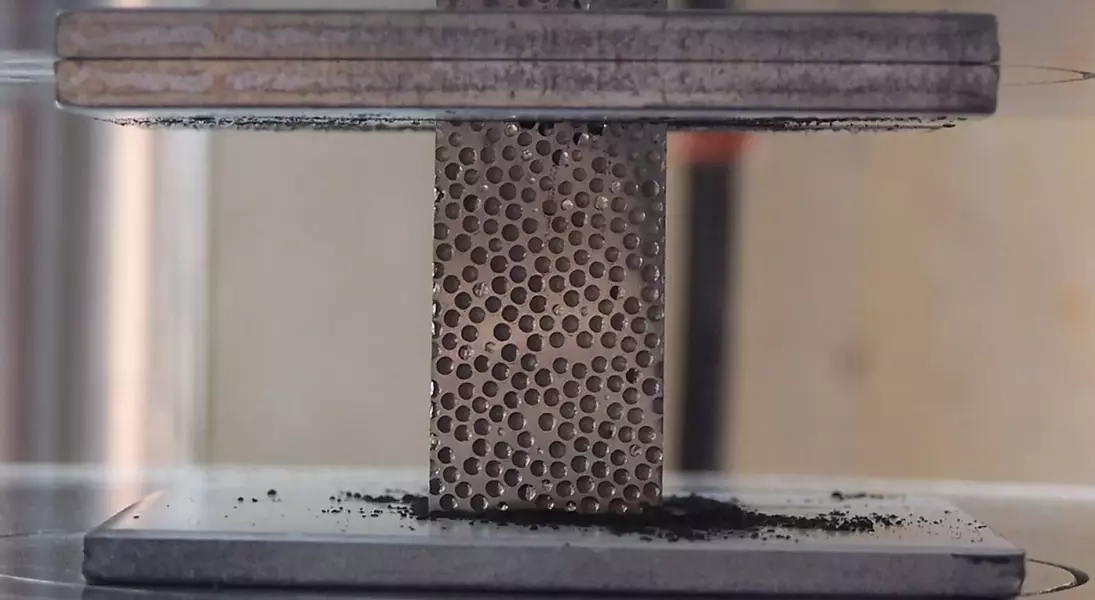

In the heart of research laboratories during the early 2010s, Dr. Afsaneh Rabiei introduced a revolutionary material that could change the future of manufacturing. Composite Metal Foam (CMF) consists of hollow metal spheres embedded within a solid matrix of steel, titanium, or aluminum alloys. This innovative structure not only reduces weight but also enhances durability and resilience under harsh conditions.

Years of rigorous evaluations have demonstrated CMF's exceptional capabilities. In a notable study published in 2019, researchers found that vehicle armor constructed with CMF could effectively stop high-caliber rounds while weighing less than half of traditional steel armor. Moreover, CMF has proven superior in thermal insulation, taking twice as long to heat up compared to solid metals when exposed to intense flames. These attributes make CMF particularly valuable for protecting sensitive equipment and personnel in extreme environments.

Dr. Rabiei's team also discovered that CMF excels in shielding against harmful radiation. A 2015 study revealed its effectiveness in blocking X-rays, gamma rays, and neutron radiation, making it a viable option for safeguarding astronauts during space missions or securing hazardous materials on Earth.

The potential applications of CMF are vast, extending from enhancing vehicle safety and fuel efficiency to improving protective gear for military personnel. As Advanced Materials Manufacturing prepares for large-scale production, the material's versatility and performance promise to revolutionize numerous industries.

From a journalist's perspective, the emergence of CMF underscores the importance of continuous innovation in materials science. It challenges manufacturers to rethink conventional approaches and embrace new technologies that offer superior performance without compromising safety. The successful transition from laboratory to market may inspire further breakthroughs, driving progress across multiple fields and setting new standards for material engineering.