Porsche is on the verge of revolutionizing its hybrid vehicle lineup with an ingenious new system designed to significantly reduce weight and boost power. This innovation centers on axial flux motors, a burgeoning technology gaining traction in high-performance automotive circles. Companies like Ferrari and Lamborghini have already adopted these motors, known for their minimal mass, compact form factor, and impressive output, into their most recent models.

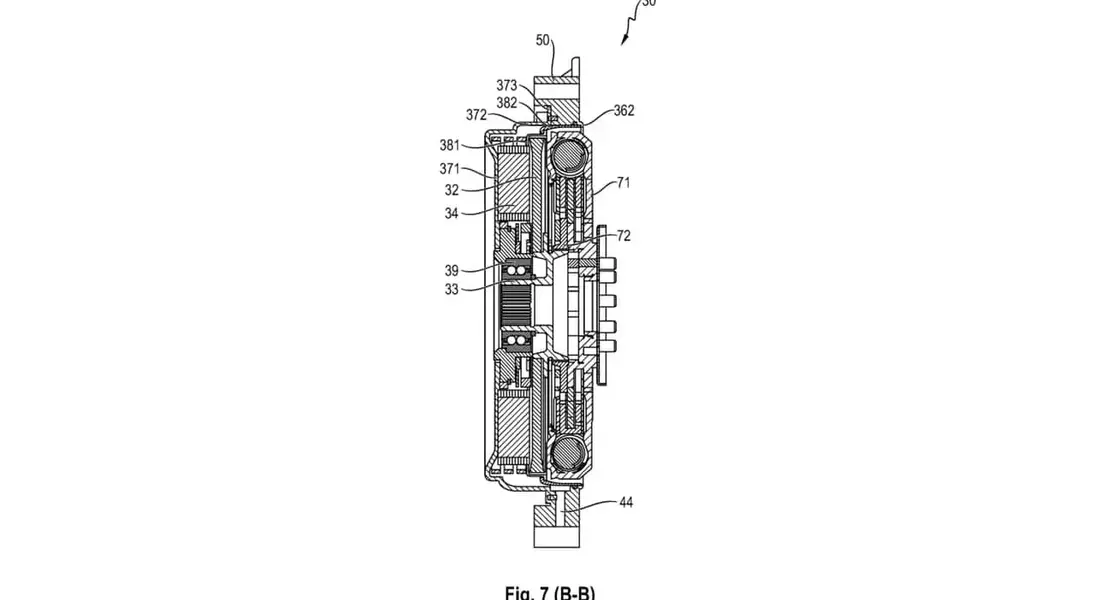

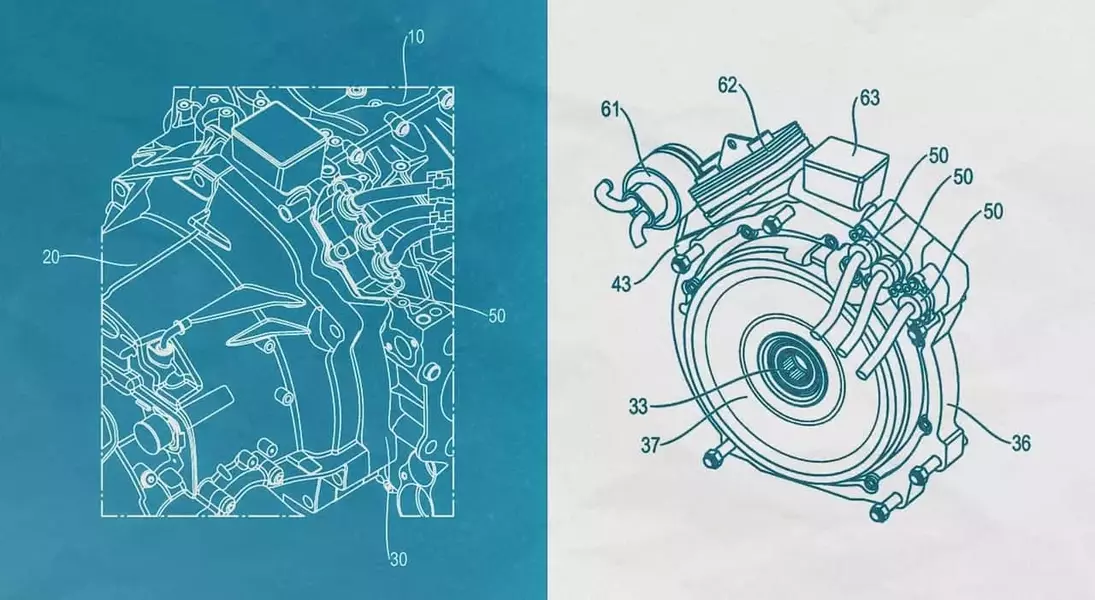

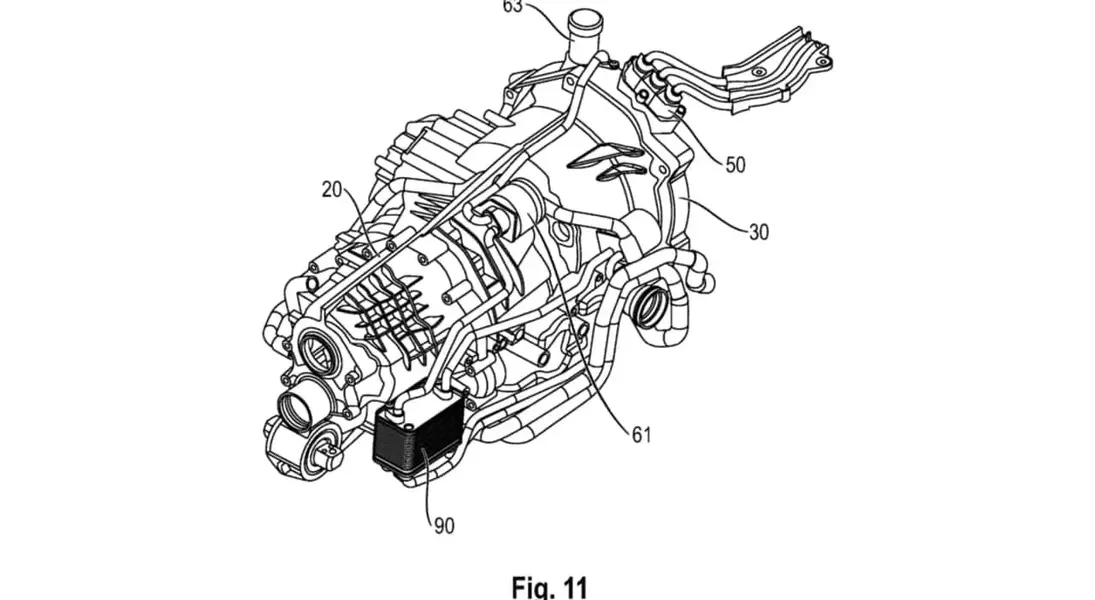

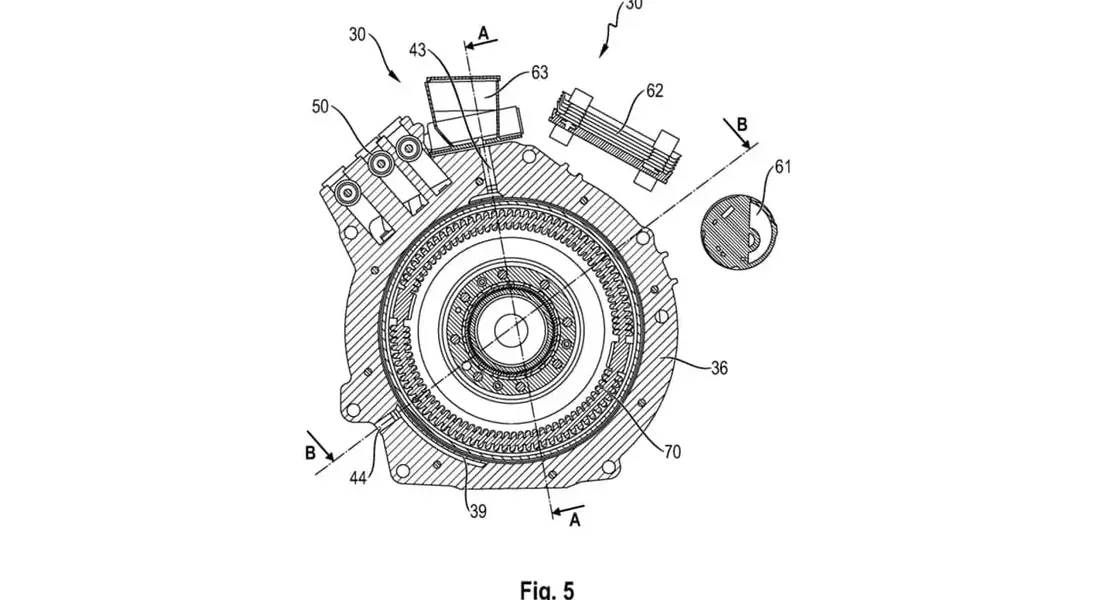

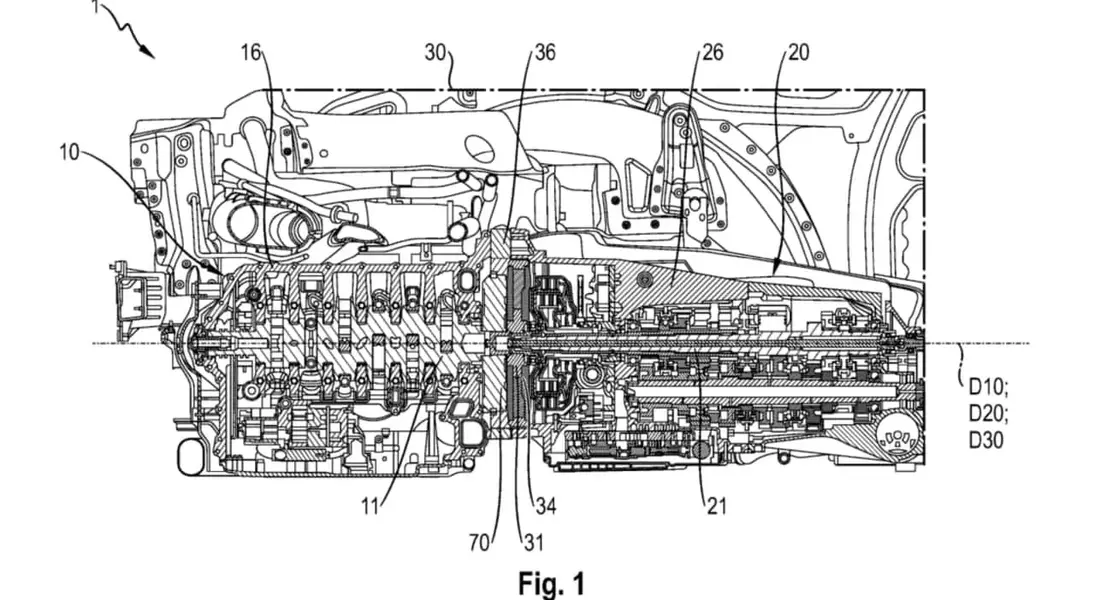

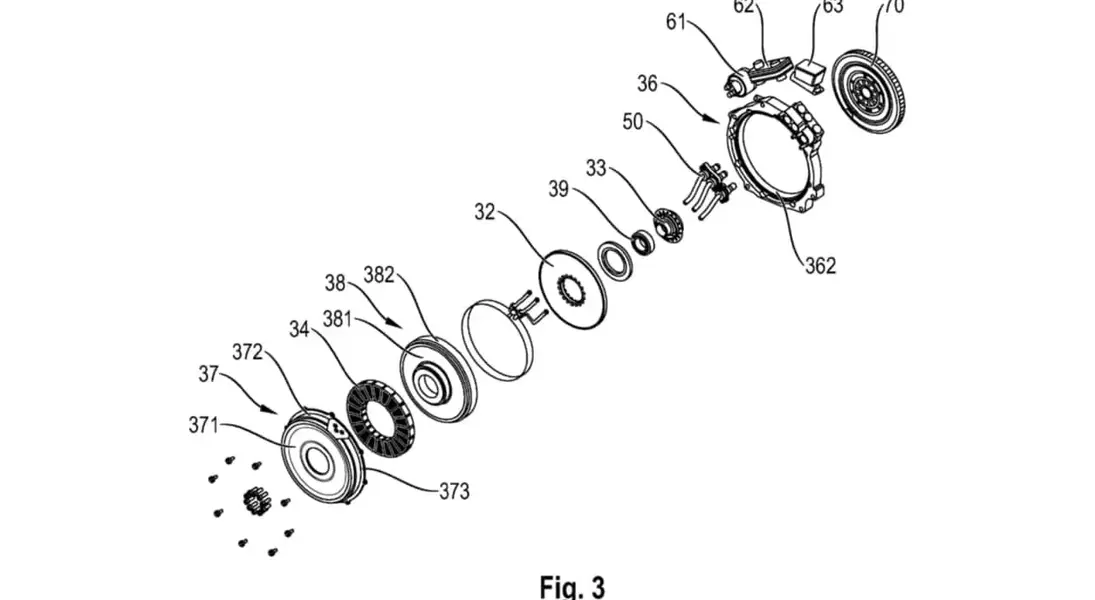

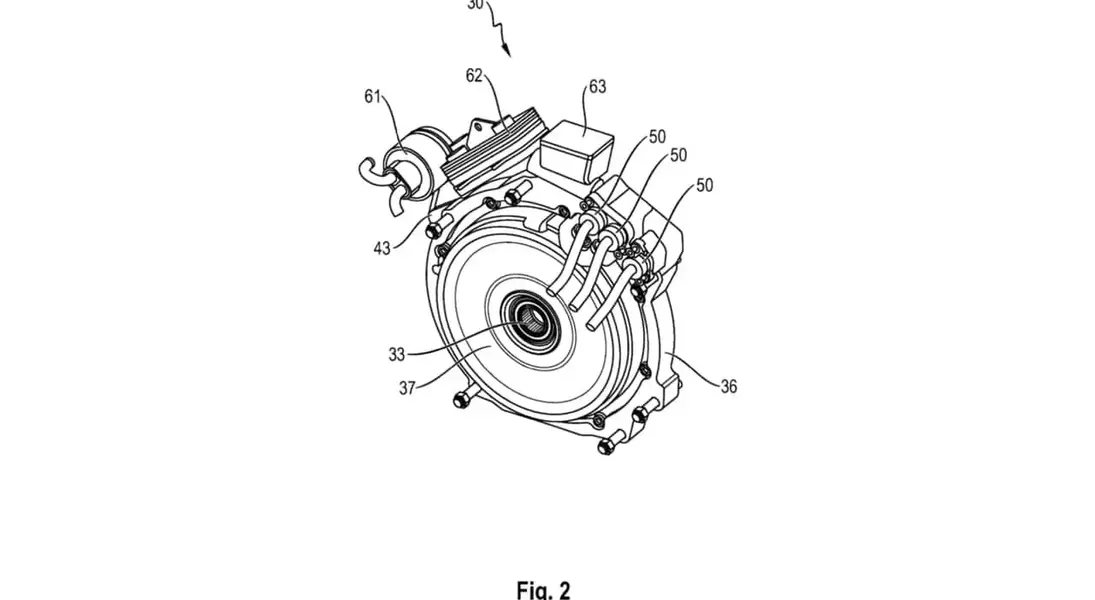

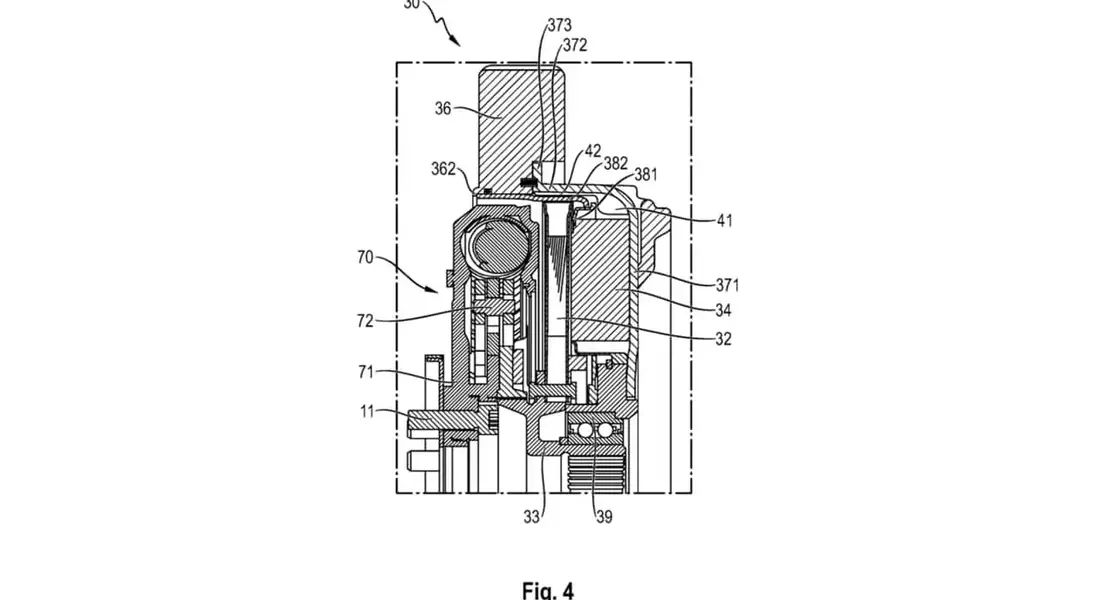

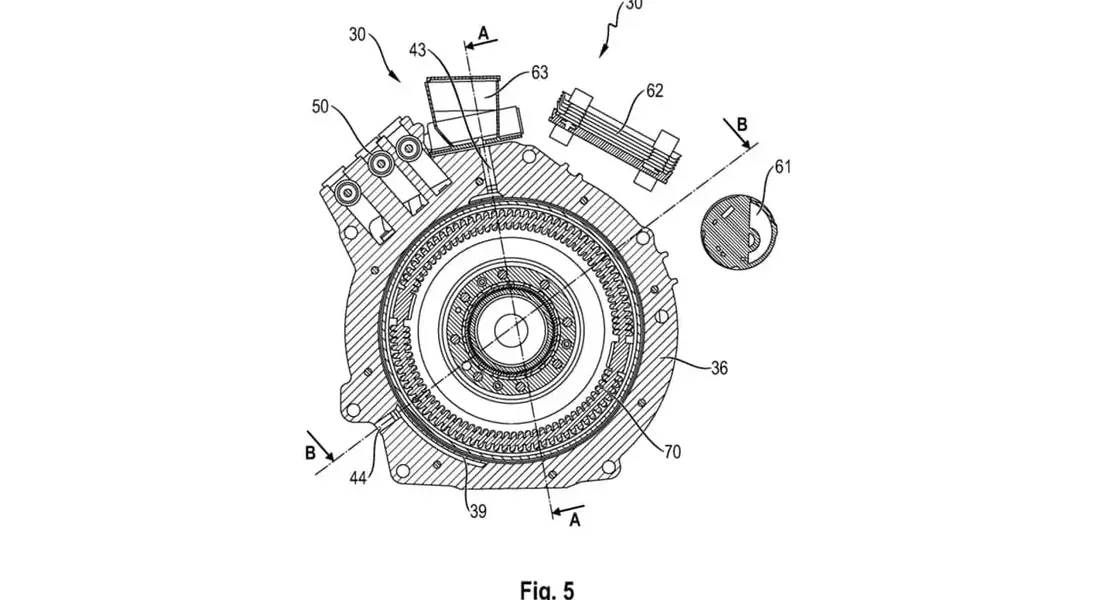

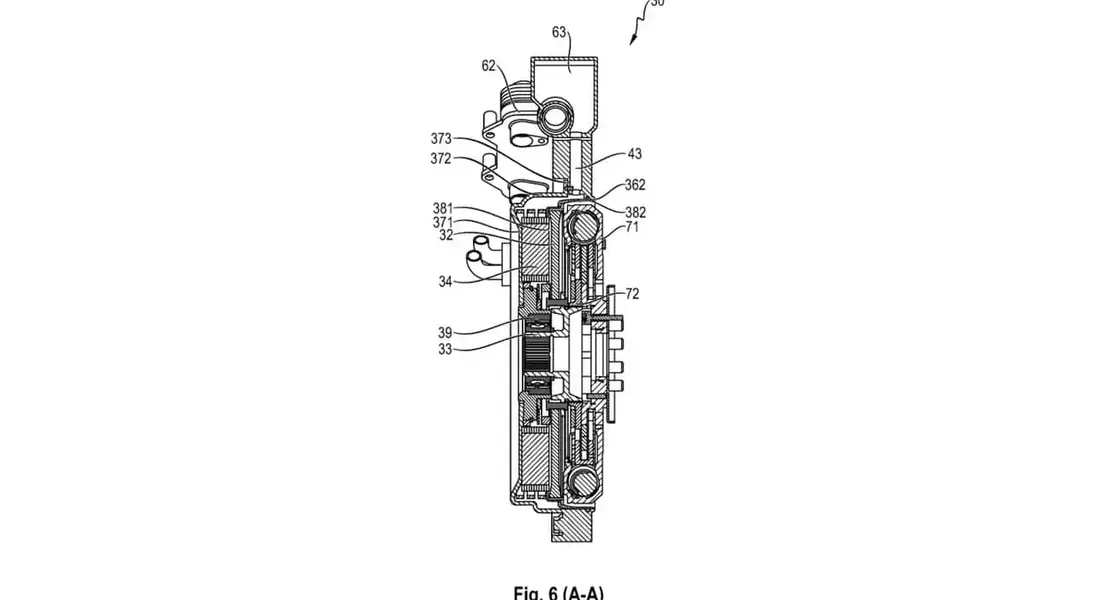

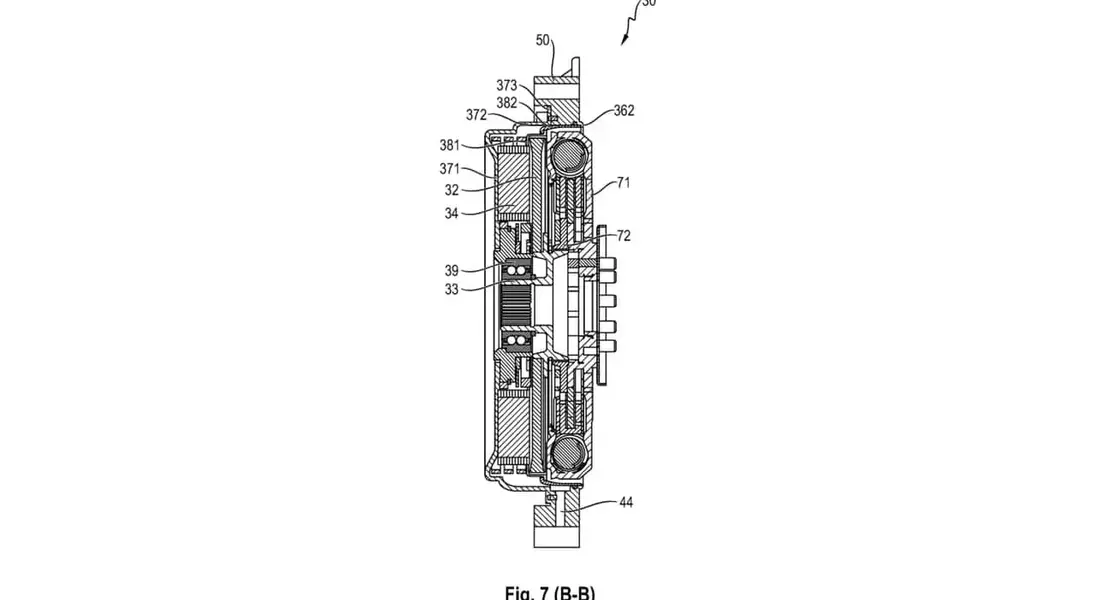

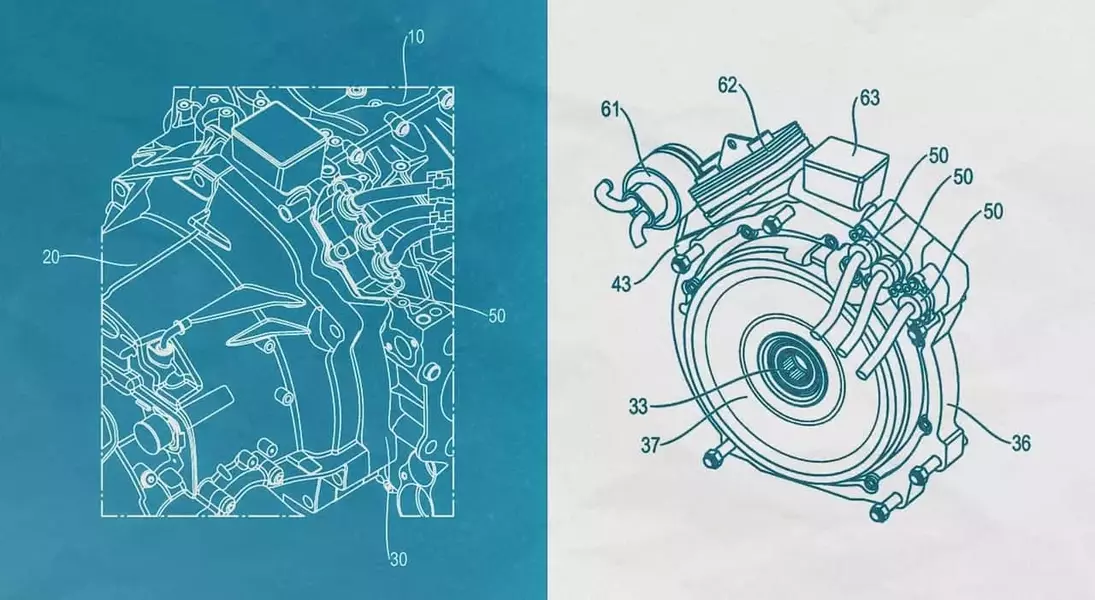

According to a patent filing with the World Intellectual Property Organization, Porsche's strategy involves integrating slim, disk-shaped axial flux motors, supplied by Yasa, directly between the engine and transmission, nestled within the dual-mass flywheel assembly. This design marks a departure from Porsche's current approach, which typically fits bulkier radial flux motors into the PDK gearbox. While the patent broadly covers passenger vehicles, it specifically highlights applications for sports cars, indicating a focus on enhancing the performance credentials of its high-end models.

The proposed hybrid powertrain is engineered to couple the electric motor with a combustion engine via a dual-clutch gearbox. A key advantage of this setup is the axial flux motor's exceptionally thin profile, which can be as slender as 3.1 inches in some existing applications. This compactness ensures that the integration of the electric motor does not add substantial length to the overall powertrain, allowing for the engine and electric motor to be efficiently positioned behind the driver without compromising vehicle dynamics or packaging.

Furthermore, the patent details suggest that this configuration is designed to generate less heat compared to conventional systems. When combined with a specialized "cup- or bell-shaped" permeable chamber, both the electric motor and the combustion engine are expected to benefit from enhanced cooling. This thermal management improvement is crucial for maintaining optimal performance in high-stress, high-power environments typical of sports cars.

The potential power figures from this advanced hybrid system are truly exciting. Yasa's axial flux motors are renowned for their high torque delivery, with some configurations capable of producing over 470 horsepower and 590 pound-feet of torque independently. For context, the Ferrari SF90 employs three Yasa motors to add 217 hp to its V8 engine, while the Lamborghini Revuelto uses two Yasa motors for nearly 296 hp, contributing to systems that exceed 1,000 hp. If Porsche implements this technology in future production vehicles, the performance gains could be substantial.

Considering that the electric motor in the current 911 Carrera GTS contributes approximately 54 hp and 110 lb-ft of torque, yielding a combined output of 532 hp and 449 lb-ft with its flat-six engine, a transition to Yasa's axial flux motors could dramatically alter these numbers. Should Porsche pair these new motors with a derivative of its turbocharged 3.6-liter engine, the combined horsepower could realistically surpass 800 or even 900 hp, depending on the specific model. This level of power would be ideally suited for high-performance variants such as GT2, GT3, or even a future hypercar, hinting at an exhilarating new era for Porsche's performance vehicles.

While many specifics regarding this patented technology remain speculative, the inherent potential for significant advancements in weight reduction and power augmentation is undeniably captivating. This move underscores Porsche's commitment to innovation and its ongoing quest to refine the performance and efficiency of its iconic sports cars, promising a future where hybrid technology elevates the driving experience to unprecedented levels.